Copper Extraction

Samples collected from drilling are analyzed to determine the grade and extent of copper mineralization.Geostatistical techniques are used to estimate the size and grade of the copper deposit.

The mined ore is crushed and ground into fine particles to facilitate the separation of copper minerals from the gangue.

The ground ore is mixed with water and chemicals to create a froth that selectively attaches to the copper minerals, allowing them to be separated from the rest of the ore. The froth containing copper concentrate is further processed to remove impurities and increase the copper content.

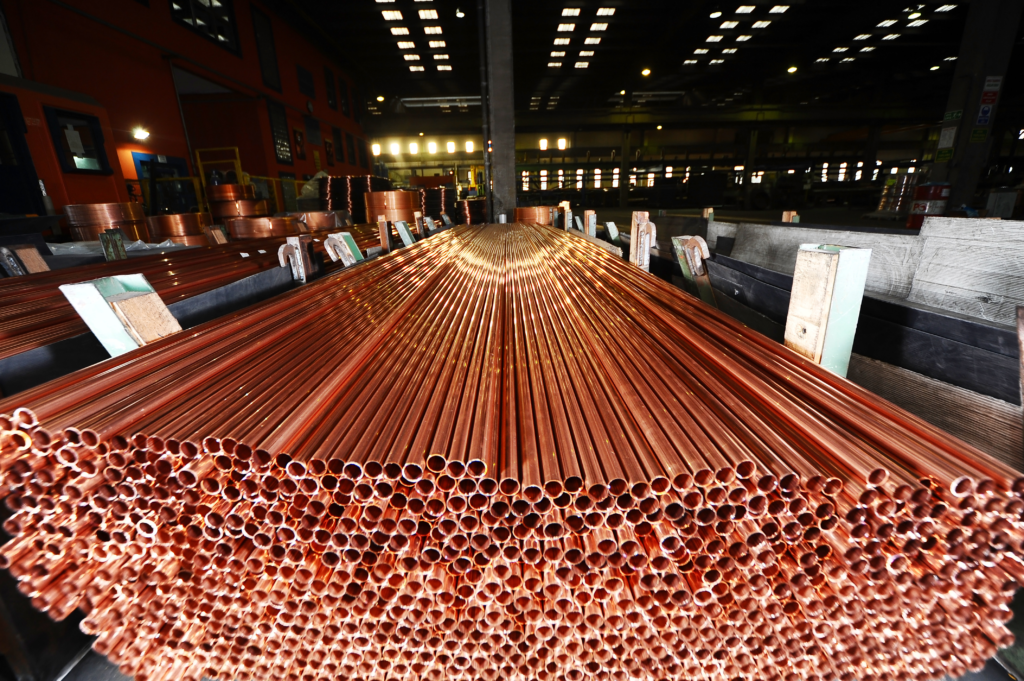

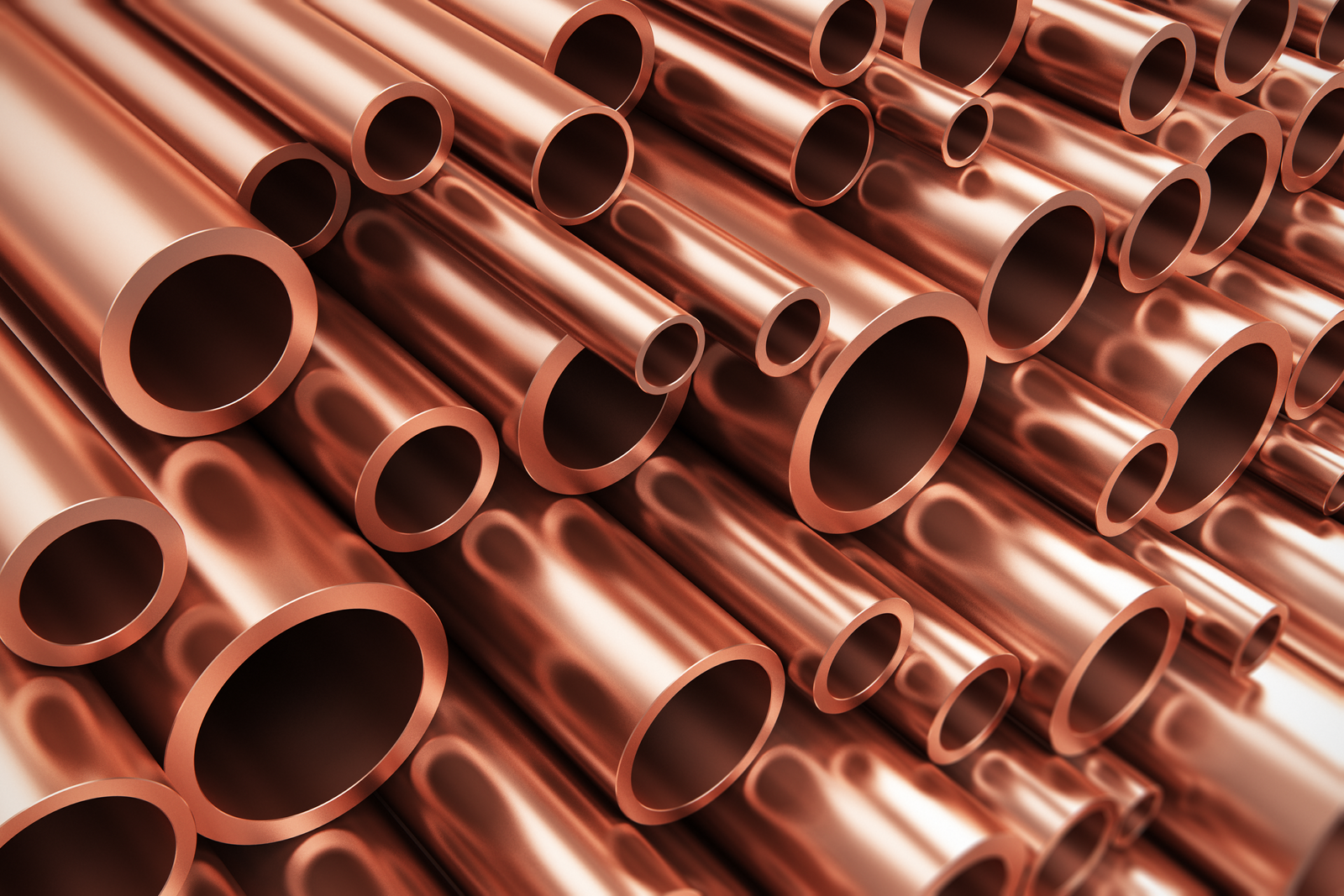

- Heating the copper concentrate in a furnace to separate the copper from sulfur and other impurities, producing copper matte. Electrolytic refining or other processes to purify the blister copper and produce high-purity copper cathodes.